Selecting the correct material for an optical component is the most critical step in lens or window design. The “perfect” material does not exist. Instead, engineers must balance transmission range, refractive index, thermal stability, and cost.

Whether you are designing for Deep UV lithography or Long-Wave Infrared (LWIR) thermal imaging, this guide breaks down the industry-standard materials and their target spectra.

1. The Ultraviolet (UV) Spectrum (10 nm – 400 nm)

Working in the UV range requires materials with high bandgap energy to prevent absorption. Standard optical glasses are usually opaque below 350 nm. Therefore, specialized crystals and silicas are required.

- UV Fused Silica: This is the gold standard for UV applications. It offers excellent transmission down to 195 nm and has a very low coefficient of thermal expansion.

- Magnesium Fluoride (MgF2): This is a rugged, durable material with a very low refractive index. It transmits down to 120 nm (Vacuum UV). Because it is highly resistant to thermal and mechanical shock, it is a “harder” alternative to other fluorides.

- Calcium Fluoride (CaF2): Engineers use this for deep UV applications down to 180 nm. While it offers high transmission, it is more sensitive to thermal shock than Magnesium Fluoride.

2. The Visible Spectrum (400 nm – 700 nm)

The visible range is dominated by oxide-based glasses. In this spectrum, managing color distortion (chromatic aberration) is the primary goal. Designers evaluate this using the Abbe Number, which describes how much the glass disperses light based on its refractive index.

- N-BK7 (Schott): This is the most common “Crown” glass. It is cost-effective, durable, and offers excellent transmission across the visible and Near-IR spectrums.

- Sapphire (Al2O3): Sapphire is highly durable and scratch-resistant. Although it is more expensive to machine, its wide transmission range from the UV to the Mid-IR makes it ideal for rugged environmental windows.

3. How to Select Optical Materials Based on Target Spectrum

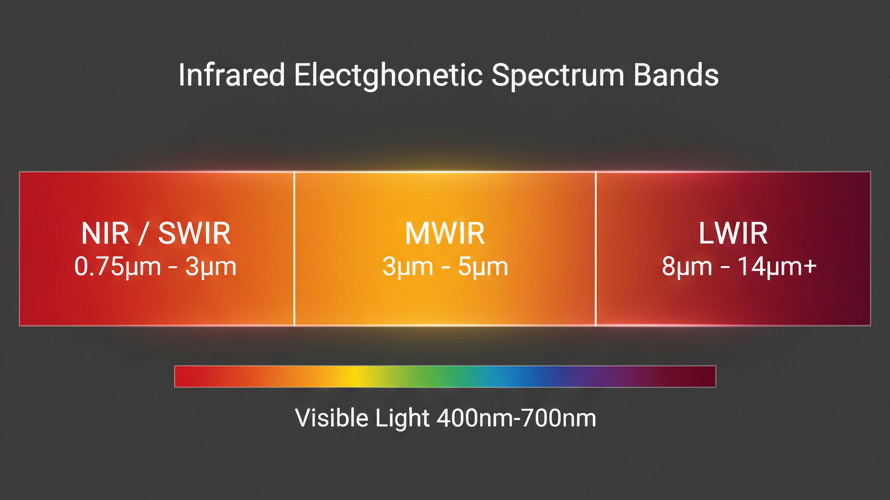

Selecting optical materials and target spectrum requirements often leads engineers toward the Infrared (IR) spectrum. This range is typically divided into three sub-bands, each requiring specialized materials that are often opaque to the human eye.

Near-Infrared (NIR) and Short-Wave IR (SWIR)

In the 0.75 to 3 micron range, Fused Silica and N-BK7 are still effective. However, designers often choose Infrasil, a specialized grade of fused silica. It is optimized to remove the “OH absorption” peak that normally occurs at 2.2 microns.

Mid-Wave and Long-Wave Infrared (MWIR/LWIR)

- Silicon (Si): Silicon is a low-cost and lightweight option for the 3 to 5 micron range. It is the most common choice for MWIR imaging but becomes opaque in the LWIR.

- Zinc Selenide (ZnSe): A yellow crystalline material used frequently in $CO_2$ laser systems. It is transparent from the visible (600 nm) all the way to 20 µm.

- CVD Zinc Sulfide (CVD ZnS): Often called “FLIR grade,” this material is optimized for the 8 to 12 micron range. It is exceptionally strong—roughly twice the fracture strength of Zinc Selenide. Consequently, it is widely used in high-speed aeronautical windows.

- ZnS Cleartran (Multispectral ZnS): This is CVD Zinc Sulfide that has undergone a specialized heating process. This treatment makes the material “water clear” and extends its transmission from 350 nm to 14 microns. It is the premier choice for systems that combine visible cameras and thermal sensors.

- Germanium (Ge): Germanium is the premier material for thermal imaging. It is opaque to visible light but offers high resolution in the 8 to 12 micron band.

Optical Material Comparison Table

| Material | Target Spectrum | Transmission Range | Refractive Index | Key Advantage |

| MgF2 | VUV / UV / MWIR | 0.12 – 7.5 microns | 1.377 | Low index, extremely rugged |

| UV Fused Silica | UV / Visible | 0.19 – 2.1 microns | 1.458 | High laser damage threshold |

| N-BK7 | Visible / NIR | 0.35 – 2.0 microns | 1.517 | Cost-effective and versatile |

| Sapphire | UV / Vis / MWIR | 0.17 – 5.5 microns | 1.768 | Extreme hardness (9 Mohs) |

| ZnS Cleartran | Vis / MWIR / LWIR | 0.35 – 14 microns | 2.200 | True multispectral performance |

| CVD ZnS (Zinc Sulfide) | LWIR | 8.0 – 12 microns | 2.200 | Superior mechanical strength |

| Germanium | MWIR / LWIR | 2.0 – 16 microns | 4.003 | High res thermal imaging |

| Silicon | MWIR | 1.2 – 7 microns | 3.422 | Lightweight / Low cost |

| ZnSe (Zinc Selenide) | Vis / MWIR / LWIR | 0.6 – 20 – microns | 2.403 | CO2 Laser Compatible |